Bio-plastic 3D printed house

(Image @dezeen)

Goal 11: Sustainable Cities and Communities

Are 3D Printed Houses The Future?

How the same technology that created our BOTTLETOP store from marine plastic could change our reliance on concrete for our homes

By hannah rochell

8 december 2021

There’s no denying it: we rely on concrete. It is the second most used substance on Earth after water. In fact, if concrete were a country, it would be one of the world’s top CO2 emitters, coming in third after China and the US with a whopping 2.8 billion tonnes per year.

The main thing we use concrete as is a building material, and with the world’s urban population projected to grow by 1.56 billion people in the next 20 years, that’s definitely something we are going to need more of in the future. So how do we go about it in a more sustainable way? The answer: 3D printing.

Why is concrete so bad?

It might be strong enough to build our water defences and tower blocks, but concrete is thought to be responsible for 4-8% of the world’s CO2, with half of those emissions being produced during the manufacturing process of clinker, a vital stage of concrete-making. It’s a thirsty material, using 10% of all of the world’s industrial water; 75% of this happens in areas where water is scarce, meaning there’s less to go round for drinking and irrigation.

How does 3D printing in concrete make a difference?

3D printing concrete reduces waste because it prints exactly what the building needs and nothing more. It also means that an entire wall can be made out of one material rather than multiple components like wood, screws and insulation. This smaller supply chain means that time, resources and funds can be freed up, and in turn homes can become more built in a more affordable way. It also means that everything can be done more locally, which reduces the emissions produced by shipping. However, concrete is by its very nature an unsustainable material, which is why companies like Fortera in California have produced a low carbon concrete that reduces CO2 emissions by more than 60%, which it is using in collaboration with the 3D construction company Mighty Buildings to construct houses.

So can you make 3D printed houses out of other materials?

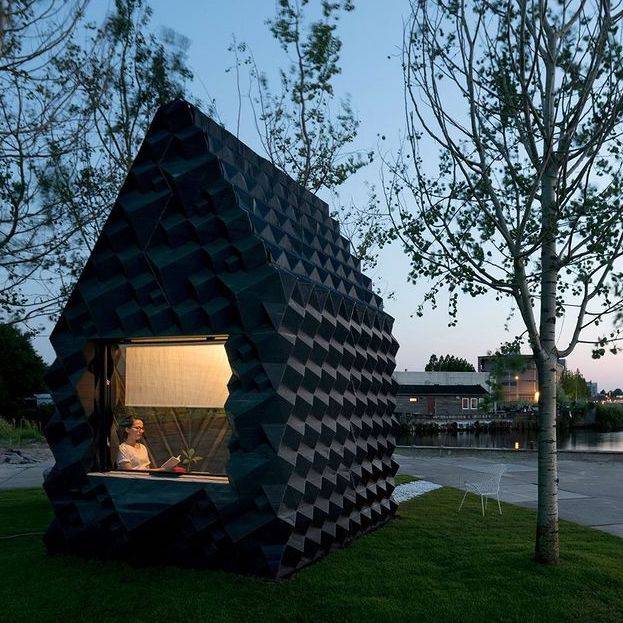

Yes! In the Netherlands, a company called DUS Architects has built a micro-cabin made from sustainable bio-plastic (pictured, top). Meanwhile in Italy, a company called WASP printed a 30 metre square house from a mixture of agricultural waste - local soil, chopped straw and rice husks, which are a byproduct of rice production. Unlike concrete, the house will naturally biodegrade if not maintained properly (which is great, since demolition accounts for 10-12% of a building’s total emissions), but if looked after shows that waste products from farming could be put to good use for our homes. And we love the cactus-like Casa Covida in the San Luis Valley, US (below), which Emerging Objects made from sand, silt, clay and water, and was designed for a couple to isolate in during the pandemic.

How long does it take to 3D print a house?

3D printing could mean saying goodbye to years of building work; in Italy, Mario Cucinella Architects and WASP used locally sourced clay to print a 60 square metre domed house. It took just 200 hours (the average house is built in 7-12 months) and used a tiny six kilowatts of power. In the US, ICON made four 3D printed houses in a week, which have also managed to withstand a 7.4 magnitude earthquake.

Could 3D houses really solve both the housing and the climate crisis?

The technology to 3D print our future homes is still very much in its infancy. Most of these houses are prototypes; Mario Cucinella’s domed house is already prone to leaks (the design is being tweaked to solve this) and all non-concrete designs are currently limited to being either one or two story, which doesn’t help much in cities where high-rise housing is needed the most. But these techniques could be suitable for sustainably building affordable homes in rural areas where the population is rapidly expanding, simply using the raw materials in the soil around them. WASP has already developed a kit with all the tools needed to do just this. It’s a starting point, and we’re excited to see where it takes us.

100% of profits from the sales of #TOGETHER products go to charities that advance the Sustainable Development Goals. Find out more here.